EconoDri Grain Transition

The EconoDri Grain Transition concept puts the same idea to work as when standing crops dry naturally on low humidity fall days.

Description

Delivering wet grain to town can mean TOO much SHRINK and TOO much drying CHARGE!

The EconoDri Grain Transition concept puts the same idea to work as when standing crops dry naturally on low humidity fall days. Combine an EconoDri chamber with VAL6 radiant energy to create the same effect.

The Unique, Patented EconoDri Grain Transition Construction Effectively:

- Eliminates radiant energy loss

- Eliminates radiant heat loss

- Reduces flow-through air humidity

- Delivers air temp rise

- Maintains vital heater operating efficiency

- Virtually eliminates monoxide and costly un-burnt fuel inefficiency. (That heavy gassy drying bin smell is FUEL that you PAID for!)

- Virtually eliminates monoxide-to-grain contamination risk

Without the EconoDri Grain Transition/VAL6 combo, as the day becomes cooler & humidity tends to rise, leaving the bin fan running can have the effect of undoing what the drying accomplished during the dry air part of the day. This happens by pushing the more-humid air into the grain.

Without the EconoDri Grain Transition/VAL6 combo, as the day becomes cooler & humidity tends to rise, leaving the bin fan running can have the effect of undoing what the drying accomplished during the dry air part of the day. This happens by pushing the more-humid air into the grain.

In contrast, the EconoDri/VAL6 combos were essentially designed to artificially create a longer drying day for the grain in the bin. This has also been proven with some grain bin after-market equipment options that operate by sensing humidity conditions & automatically operate fans as long as the day’s humidity is conductive to accomplishing drying & automatically shutting the fans when the humidity is not drying the grain. Either way, whether the EconoDri/VAL6 combo is integrated with automated fan systems or manually, the net result is for more economical, more cost-efficient drying.

The most popular VAL6 radiant space heaters consume between .85 to 1.1 gallons of diesel per hour. Compared to conventional drying systems that can consume much higher volumes of fuel, EconoDri/VAL6 combos typically translate into lower per-hour operating costs combined with a reduced tendency to over-dry and the possibility of drying significant amounts of test-weight out of the grain, with loss of income from lower pay weight.

Made in the USA!!

Made in the USA!!

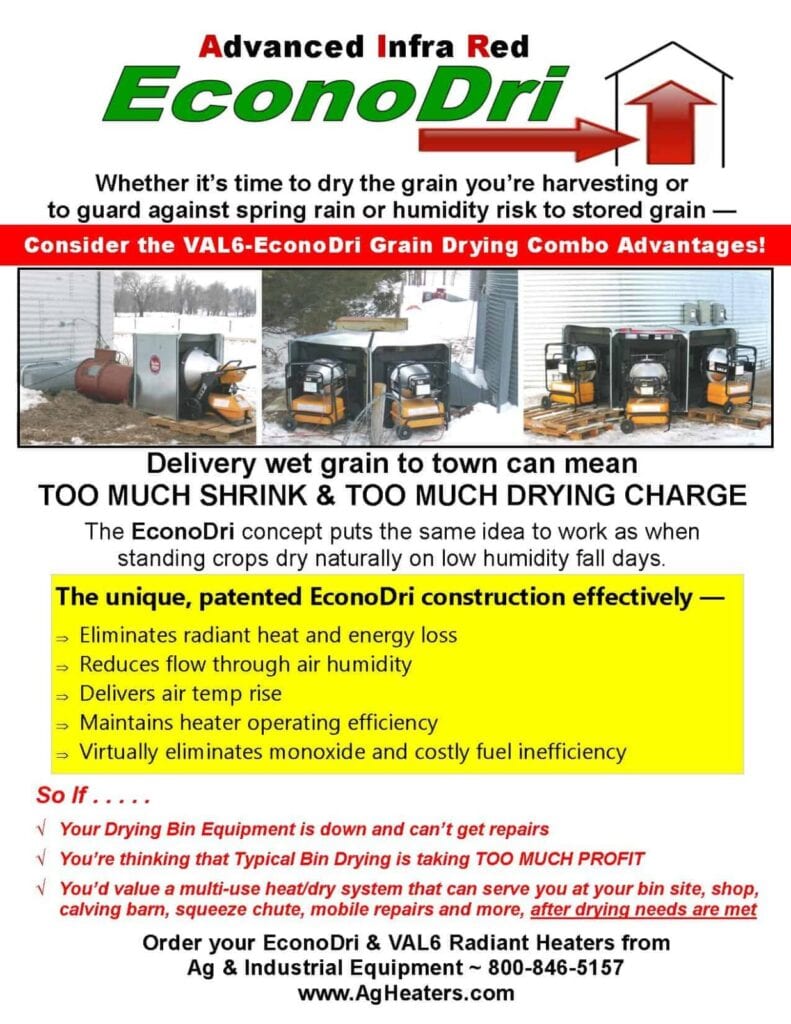

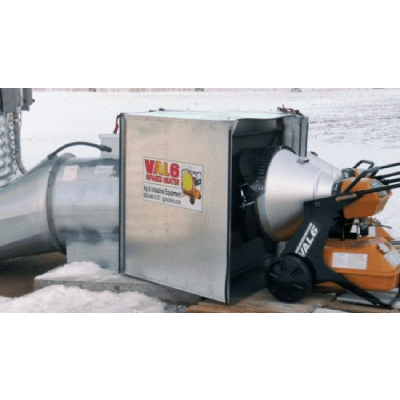

The EconoDri cabinet is designed to decelerate the air flow passing through the chamber. This slowed flow exposes the air to the extreme radiant energy slightly longer, while controlling the companion cooling effect of the air-flow, thereby maintaining the VAL6 1500° operating efficiency target. This is also magnified by the patented internal thermal energy collector assembly. The collector absorbs the radiant energy and heat through which the decelerated air-flow passes through.

The closest 60% of the EconoDri collector surfaces can temp-read absorbed temps from 250° -350°F. and more depending on the VAL6 model used. Pass-through air typically experiences a 20-40° temp rise, again depending on the size and capacity of the bin fan. This is where humidity drop and temp rise takes place. Also where the patented wrap-around EconoDri design manages/controls the performance variables mentioned earlier. The unique 360° “wrap-around” collector design also functions to minimize “escape” radiant energy and heat, and in doing so, works to maximize the intended dry air that a bin fan pulls in and forces through the grain to be dried.

Testimonials….

Originally purchased a diesel Val6. Now the Val6 and EconoDri made believers out of us for drying grain. We purchased a propane Val6 because it was a good jump bigger plus the convenience of not needing to refill the diesels.

Using them on 45,000 and 20,000 bushel bins and used to use a continuous flow and we’d go through 1000 gals of propane. The Val6 EconoDri combo can’t be beat. Then after we are done drying grain, we have many other winter uses for the Val6 heaters.

Dennis & Collin Z – Northeast, NE

I started to use Val6 radiant heaters to dry corn about 4 years ago and have been adding Val6’s to do more bins, every year since. Using 50 HP fans on 50K – 55K bins and 30 HP fans on 30K bins. Bins with 2 fans usually get a Val6 by each fan. For an example, we’ve had corn in an 18-20 harvest moisture range, fill up the bin, level it, and run the Val6’s for 2-3 weeks and they’re dry.

Easy to look for signs that the Val6 drying is working by using dry air, you don’t see the humidity accumulation in the morning from roof condensation. You always have heavy corn with Val6 drying because you’re drying with dry air, not hot air that over-heats / over-dries and scorches out the grain oils that contribute to test weight.

Another drying cost comparison example:

50K bin X 22 moisture grain

24 hours / day X 24 days = 570 hours X @ 1G/Hr fuel consumption = 570 G of #1 diesel @ 3.50 / G = $2010.

$2010 divided by 50K bushel = 4 cents per bushel dried to 15-16

Electrical costs are considered even regardless of drying model used.

Conventional burner-ring propane drying is now @ 7 cents / bushel plus electrical.

By comparison, elevators that take 1 1/2 % shrink w/ no drying charge compared to actual shrink is more expensive yet. I’ve added more Val6’s for drying to more bins. My low drying cost is just part of it. When it’s time to harvest, I have just too much investment waiting to be harvested, and I don’t want to stop and lose time shuffling grain around, I need to keep rolling. It’s easier and faster to add Val6’s to more bins to dry, than save pennies and maybe lose dollars drying and moving grain. Plus cutting out unnecessary grain moving and handling keeps my grain quality as good as possible. I have about 15 bins w/ LP and Shivers systems and no longer use them.

Furthermore, bin drying equipment is at the mercy of the elements…..

whether it’s wasps/insects building nests and hives or mice dragging in trash and storing food, or rats and mice chewing through electrical insulation, or an accumulation of chaff and dirt building up in equipment / controls or the deterioration that goes with equipment over time, as equipment ages / fatigues, whether you use the equipment or not, the cost of drying bin maintenance is not cheap. Val6 equipment is fairly easy and inexpensive to maintain and Val6’s always have other uses, too.

Michael W – Cornlea – Humphrey area

For 2013 crop year

I had 7500 bushel bins and put 22% moisture corn in / filled bin. Ran non-stop 7 days and nights. Burned 110 gallons of diesel X $4 per Gallon = $450. Cleaned the bin after 7 days & nights, corn was 15.5% – 16.5% average moisture. Corn weighed great, 63#. Took 6 points of moisture out of 7500B for $450 = 6 cents / bushel or 1 cent / point.

Ordered an additional EPX Val6 and EconoDri Combo in 2013, and dried 2 X 7500B bins at a time = 15000B, then transferred to storage.

Conclusion:

Figured the economy of drying easily paid for the Combo and the Val6 EPX and EconoDri Combo consistently proved itself. Evaluating the value of getting a Combo for each bin, and reducing / eliminating the time to transfer and the improved grain quality from reducing handling, so I purchased another Val6 EPX / EconoDri Combo for 2014.

When unloading bins, I consistently got an even 15-16 moisture and did not over-dry the bottom 25% of the bins like he typically did with open-burner conventional drying, and again, grain weight was a heavy 63#.

Also liked the versatility and additional uses for the Val6.

Keith J – Fremont, NE (area corn / soybean farmer)

In 2009, we had real wet corn and it wasn’t drying, we didn’t have drying bins, and the snow was coming. I tried the VAL6/EconoDri Combo by the bin fans and I was happy with the drying. AND happy enough to buy more Val6’s and EconoDri’s because they work!

The nice part, after the drying’s done, we use the Val6’s for winter shop work. Any bin dryer would never have done all of that!

B. W. – Central Nebraska

We bought 2 EconoDri’s & 2 KBE5L’s. We had 35,000 bu bin with 2 fans. Had 21 moisture corn & dried it to 16% in 3 weeks! 20 gal per day x 2 = 40 gal x 20 days = 800 gallons. So 800 gallon @ 2.50/gal = $2000 ÷ 35,000 bu = 5.7¢/bushel. Excellent product!

Ryan S. – David City, NE

Want more information on the EconoDri Grain Transition?

Call Jim at 800-846-5157!

Reviews

There are no reviews yet